Let’s go back, all the way back to the beginning of what we today call eCommerce. Before the wonderful world of inventory management and order fulfillment, the great ancestor of modern day eCommerce was Mail Order and it manifested itself in the form of catalogs. While the earliest known catalog dates back to Venice in 1498, the foremost mail order service in US history was the Sears Catalog est.1888. Richard Sears first created the catalog to advertise watches and jewelry, but by 1894 company ownership had shuffled around and Sears began adding everything from baby carriages to firearms. As the citizens of the new United States spread across the massive expanse of the North American continent, it became of vital importance for folks to get materials to live, grow, and build. The Sears catalog gave the people the ability to order a wide array of goods, which was important as the only other way to purchase items was on credit from local general stores with sparse inventory.

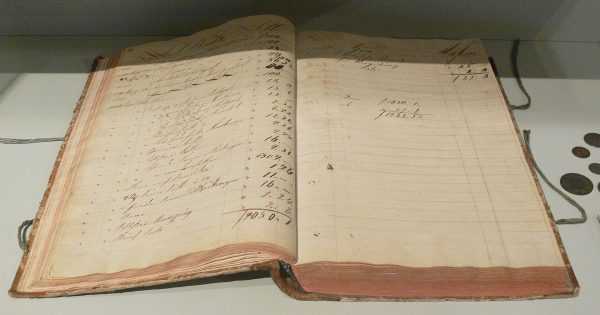

Today with Amazon and eCommerce, we buy, sell, and receive items almost subconsciously. In this brave, new, customer driven world, I like to look back and consider the stepping-stones that laid the path from the late 1800s Sears to the 2018 Amazon. Particularly, as Shipedge works with many etailers and 3PLs, I have become fascinated with inventory management. Consider Richard Sears: what was his inventory management like? In the beginning, I am sure it was just labeled boxes on a shelf managed by a hand written ledger. As Sears began to diversify its offerings and produce catalogs boasting a cartoonish 500 pages, things must have become more complicated. At this point I, like the rest of the United States, am going to leave Sears behind. Instead, I want to consider the evolution of inventory management and what inventory control has done for eCommerce.

Inventory Management

Inventory management exists mainly as a concept. By this I mean that the ability to manage one’s inventory is a goal, but to do so you will need to utilize the tools that are available. These tools keep up with how many units you have for each SKU (product variation) at any given time. A hand written ledger was the longest standing standard for all things inventory and finances. Fortunately, technology has advanced enough for us to leave the pen and paper behind.

Warehouse Management System

The next step in the evolution of inventory management is the Warehouse Management System. Warehouse organization is not exactly a new concept. Really from at least as far back as the ancient Egyptians until the advent of the railroad, not much has changed in the world of warehouse management. There were organized storehouses for the inventory control of grains and goods, but once the locomotive began traversing long distances the railroad companies held a monopoly on the shipping and storage industries. If there was a warehouse management system in play, it did not advance beyond that beautiful ledger. The main difference was the number of and distance between warehouses. From about 1900 to 1940 warehouses were organized haphazardly in large stacks, but they did finally begin to utilize the hand truck. Not surprisingly, WWII brought on a new era of the warehouse with forklifts and pallets. Toward the 1970s inventory and warehouse management became a bit simpler with the advent of the computer and the Automated Storage and Retrieval Systems (AS/RS).

Interestingly, in the 1980’s the AS/RS systems began to disappear as the excess in inventory led to an increase in storage costs. In an effort to reclaim inventory control, warehouses focused on decreasing their inventory to smaller batches using database systems. These systems updated at regular intervals, which is in some ways that foundation of the warehouse management systems we have today. At the turn of the millennium computers were faster and databases more robust. This paved the way for the modern Cloud Based WMS.

Today Warehouse Management Systems will not only keep up with inventory counts, but also control the flow of units by mapping the warehouse, managing locations for each products, and most importantly, managing the people that deal with inventory. Traditionally the WMS will take orders from selling systems, like an ERP or a CRM.

Enterprise Resource Planning (ERP)

Let’s pretend you want a lemonade stand. First you go to the store, buy the ingredients, and make lemonade – that is your inventory. You put your lemonade and remaining ingredients in your fridge (warehouse), organize it (WMS), and take it out of the fridge when you need more (also WMS). The last piece of the puzzle is deciding where to sell your lemonade and this is where your ERP comes into play. An ERP can manage the finances of your operation, has forecasting algorithms, and empower you to grow your company. If you’ve been able to follow along then you might recognize the trend with inventory management software. Inventory management used to be so simple, but as the global economy developed and new marketplaces like Amazon arrived on the scene, everything got a lot more complicated. A warehouse management system controls inventory, controls your warehouse, and, if it is good, ensures that you operate at peak efficiency. Now, you are looking to expand further and that is what an ERP can help you do.

The eCommerce Era

Let’s put this all together. Sears helped to create a world where you can order things that are not immediately available at a set price. A century later, we are doing the exact same thing, but instead of a catalog we use the Internet. The Internet connects us to suppliers and customers; so today we do not ever have to touch a product in order to sell it. Instead we use stores like Amazon, Ebay, Walmart, Shopify, etc. We can even sell our products on all of these channels, making us multi-channel etailers.

As these etailers grew in number and fortitude, the brick and mortar retailers also began selling online in order to reclaim market share. That was the birth of OmniChannel, which add brick and mortar stores to multi-channel ecommerce. These retailers now have multiple channels online, in store sales, sales in partner stores, online marketplaces, and finally an online company store.

Each of these different channels represents a different area in which inventory must be managed. Warehouses, brick and mortar stores, distribution centers, and 3PLs all count as inventory locations. That means that you need a warehouse management system that can provide inventory management no matter where your inventory is. Not only does this save you from back orders, but also having a WMS that works congruently with an ERP helps you decipher which channels and products you want to keep, where you can grow, and what avenues to pursue.

The End?

A warehouse management system that manages inventory, optimizes warehouses, and has ERP functionality is a necessity if you want to succeed selling online. No matter how excellent your product or service, if you do not have the logistics backbone to support your organization then you cannot succeed. That is the state of the industry today, but if history is our map then we can expect eCommerce to continue to evolve. If you want a system that grows limitlessly and adapts to new trends, then Shipedge may be the answer for you. To learn more or ask questions, you can contact Shipedge here.